The plaything industry has been one of the most prolific plastic production markets over the past few years. With millions of playthings created, together with profits of over billions of dollars on a yearly basis, the plaything industry has assisted the plastic market turn into one of the globe’s greatest and also most respected markets.

When it comes to plastic injection molding, China is just one of the most significant suppliers of plastic to plaything suppliers worldwide, supplying both the raw product, together with the manufacturing tools and modern technology that assist produce toys of the very best high quality. This innovative production modern technology not just created the very best items yet likewise presented a brand-new approach called multi-color plastic shot molding.

This production technique has actually been one of the most ingenious molding approaches and has aided generate today’s generation of quality playthings. With that in mind, here’s what you require to know about multi-color injection molding.

What is Multi-Color Plastic Injection Molding?

The typical procedure of producing plastic components and items using shot molding equipment includes injecting one shade per component at a time. While this process is still typical in a great deal of factory throughout the world, this procedure can be very inefficient, especially for the toy industry, which needs to create utilizing a wide variety of shades for each and every part.

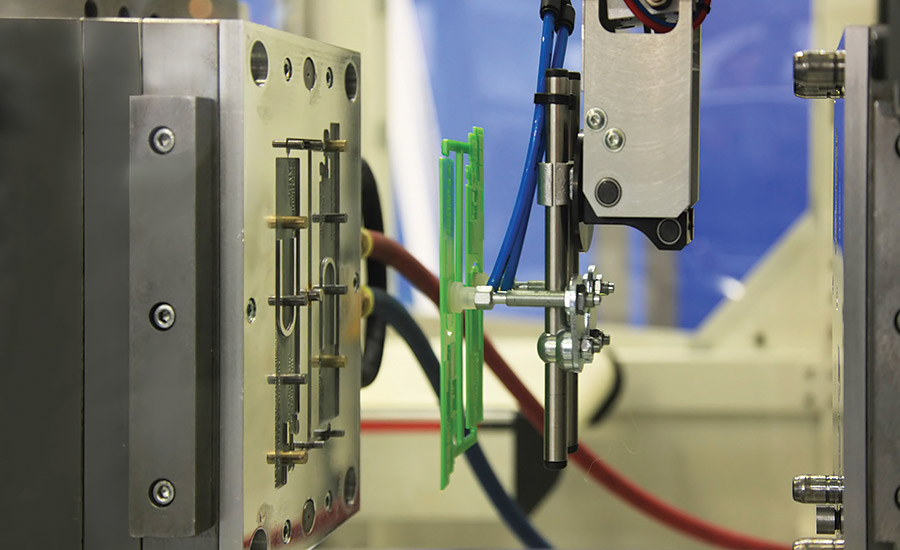

This is where multi-color plastic shot molding comes into play. The procedure entails including another collection of plastic pellets to include another shade that would certainly be integrated into the very same plastic mold. Some of these multi-color plastic injection molding makers can manage at least 2 shades at the same time, with the alternative to include more colors if needed. Infusing multiple colors into a single mold and mildew is a fragile process that needs correct sequencing in order to not mix with the primary color.

After the required modifications and also the molding procedure, you will be able to produce a multi-color plastic product efficiently. This process is also extra cost-efficient, as you would no longer need to generate some parts individually, which can take more time to put together, as well as can also cost even more.

The technology to create the multi-color plastic shot molding process is one that took years of research and development to achieve. Ultimately, the plastic production business, which includes shot molding from China, developed their own concepts and also requirements that permit them to complete the process, and make it suitable for mass-production of plastic products. This ultimately caused even more plastic production companies to suit their needs and also produce their very own collection of multi-color injection molding devices.

Impact on the Toy industry

Toys are not just one of the most prolific products worldwide, however, they were also among the drivers for innovation in the plastic production sector. Starting out with straightforward plastic mold and mildews to develop products that are easy to create as well as disperse, toys at some point came to be a lot more complicated as the years went on, with even more components as well as features that required to be fit.

This also resulted in innovations in plastic toy design, a few of which are called for to be formed in a multitude of shades. This process called for equipment that can infuse different shades into numerous parts, which is a more efficient process contrasted to repainting the components after being eliminated from their mold and mildews and joggers. This efficiency assisted playthings to become much easier to produce, while also providing possibilities to craft more diverse as well as cutting-edge toy layouts.

Notable examples of multi-color plastic shot molding can be seen on toys such as plastic bricks, activity figures, and also even model packages. For the latter, model packages have actually greatly benefitted from multi-color shot molding, as a model set businesses have the ability to inject multiple colors right into a single jogger, making the procedure of assembling a lot more hassle-free experience for the plastic modeler. The exact same opts for activity figures, as the procedure of providing the essential colors can already be carried out in the molding procedure itself.

Multi-color plastic shot molding has considerably assisted the plaything sector right into pressing in the direction of innovating their techniques in layout and production, ultimately bring about far better quality items. As the plaything industry continues to expand, anticipate multi-color plastic shot molding innovation to play a big role in shaping the developments in the plaything market, and also continue to turn into one of the most prolific plastic item producers in the world.

Conclusion

The toy sector remains to become one of the largest plastic production sectors on the planet, and that is many thanks partly to the advancements bought about by multi-color plastic shot molding. The ease bought about by this technology has actually helped shape the toy industry right into the plastic creating giant that it is today, offering better-created playthings while making the whole production procedure that much easier. The next time you take a look at several of the most recent plaything products, you’ll be able to see the elements of the multi-injection plastic molding in their design.